Uncovering the Important Applications of Aluminum Castings Across Various Sectors

Aluminum spreadings play a necessary duty in several sectors. Their light-weight and resilient qualities contribute to advancements in vehicle and aerospace markets. Additionally, they enhance building stability and consumer product layout. As sustainability comes to be a top priority, the ecological advantages of light weight aluminum spreadings additionally highlight their significance. Recognizing the considerable applications of this product can disclose understandings into modern-day production methods. What details innovations are being made in these numerous markets?

Automotive Market Innovations

In addition, light weight aluminum castings play an important function in electrical vehicles, where weight decrease is paramount for battery effectiveness. With the combination of aluminum in engine blocks, transmission real estates, and structural elements, car manufacturers can accomplish premium toughness while keeping peak performance. As the need for lasting and effective lorries grows, the auto market continues to embrace aluminum spreading technologies, positioning itself at the center of technological developments and environmental duty.

Aerospace Advancements

While the aerospace market constantly looks for ways to boost efficiency and effectiveness, improvements in light weight aluminum castings have actually arised as a crucial aspect in accomplishing these goals. The lightweight nature of light weight aluminum significantly contributes to sustain efficiency, lowering overall aircraft weight without jeopardizing structural stability. Innovations in casting techniques, such as die spreading and financial investment casting, permit for complex designs that enhance aerodynamics and performance.

Improvements in metallurgy have actually boosted the strength and deterioration resistance of aluminum alloys, making them appropriate for various aerospace applications, including engine elements and body frameworks. The capacity to create intricate forms minimizes the number of parts called for, improving assembly procedures and lessening maintenance needs. As aerospace makers significantly turn to aluminum spreadings, they are locating that these advancements not just drive functional efficiency however additionally sustain sustainability objectives via reduced power intake throughout trip.

Building Applications

Light weight aluminum castings play a pivotal duty in the building and construction sector, providing a combination of strength, sturdiness, and light-weight residential properties that boost architectural honesty. Metal Castings. These castings are used in a variety of applications, including window structures, door frames, and roof, where their resistance to deterioration and weathering is especially beneficial. Light weight aluminum castings contribute to energy effectiveness, as their light-weight nature reduces the general load on structures, facilitating easier transport and installment.

In addition, the versatility of light weight aluminum permits intricate geometries and detailed styles, conference visual requirements without jeopardizing architectural efficiency. In seismic regions, aluminum castings can be utilized in important architectural parts, offering considerable benefits pertaining to adaptability and strength. Generally, making use of aluminum spreadings in building not only enhances the performance of buildings however likewise sustains sustainable structure techniques by allowing using recyclable products in building jobs.

Customer Goods Manufacturing

In customer products producing, aluminum spreadings play a crucial function in lightweight item style, allowing for simpler handling and improved effectiveness. Their improved sturdiness attributes add to the longevity and reliability of day-to-day products. This combination of benefits makes light weight aluminum a preferred product in the competitive durable goods market.

Lightweight Product Style

As producers progressively focus on performance and sustainability, light-weight product layout has emerged as an essential element of durable goods growth. The integration of light weight aluminum spreadings enables developers to create items that are not only lighter however likewise a lot more energy-efficient. This reduction in weight adds to decrease transport costs and improved customer experience, as customers progressively look for easier-to-handle products. Furthermore, light-weight layouts facilitate ingenious visual appeals, making it possible for brand names to separate themselves in an affordable market. The adaptability of aluminum permits complex forms and kinds, improving total layout flexibility. Subsequently, light-weight item layout is coming to be important for firms aiming to meet modern consumer demands while adhering to environmental considerations. This trend is improving just how products are conceived and made throughout various markets.

Improved Longevity Features

While modern customers require items that are both light-weight and visually pleasing, boosted durability features have ended up being similarly find out essential in durable goods producing. Aluminum spreadings use phenomenal strength-to-weight ratios, permitting makers to produce products that endure daily damage. The inherent corrosion resistance of light weight aluminum warranties that items preserve their look and capability gradually, decreasing the need for regular substitutes. In addition, casting techniques enable the production of smooth designs that enhance structural integrity. Consequently, makers can supply durable goods that not only fulfill efficiency assumptions however additionally offer longevity. This emphasis on durability not only boosts consumer contentment however additionally straightens with sustainability objectives by minimizing waste and promoting liable consumption.

Electric and Electronics Market

The electric and electronics field significantly depends on light weight aluminum spreadings for their lightweight, resilient, and very conductive residential or commercial properties. These spreadings are indispensable in manufacturing numerous components, including real estates, units, and warmth sinks. Their low density enables lowered total weight in electronic devices, enhancing mobility without jeopardizing efficiency. Additionally, aluminum's outstanding thermal conductivity is necessary for dissipating warmth produced by electronic elements, ensuring perfect working and longevity.

Light weight aluminum spreadings supply exceptional deterioration resistance, which is critical for maintaining electronic honesty in numerous settings. The capacity to produce complicated forms and complex layouts through casting methods further sustains innovation in item growth, permitting suppliers to satisfy particular technical requirements. As the need for high-performance and energy-efficient digital devices continues to grow, light weight aluminum spreadings are positioned as an essential product, assisting in innovations in innovation throughout the industry. Their versatility and integrity make them vital in the modern electric and electronics landscape.

Sustainability and Environmental Influence

Recognizing the growing problem for environmental sustainability, the aluminum casting sector has made considerable strides in minimizing its environmental impact. The production of light weight aluminum spreadings now significantly makes use of recycled materials, minimizing power consumption and resources extraction. This shift not just saves sources however additionally lowers greenhouse gas exhausts connected with primary light weight aluminum production.

Furthermore, improvements in modern technology have actually caused more effective spreading procedures, additionally lowering waste and enhancing power performance. Many suppliers are embracing sustainable methods such as closed-loop systems that reuse water and minimize commercial waste.

Light weight aluminum's light-weight nature improves gas performance in transport fields, adding to reduced exhausts over the lifecycle of lorries. As the sector proceeds to prioritize and innovate sustainability, aluminum spreadings are positioned to play a crucial function in promoting eco liable methods throughout various markets, straightening with worldwide initiatives to deal with climate change and advertise sustainable advancement.

Regularly Asked Inquiries

What Are the Conveniences of Aluminum Castings Over Other Materials?

Light weight aluminum spreadings provide light-weight homes, outstanding corrosion resistance, and excellent thermal conductivity. In addition, they enable elaborate designs, minimize production costs, and provide boosted longevity, making them helpful contrasted to conventional materials like steel or iron.

Exactly How Are Aluminum Castings Produced?

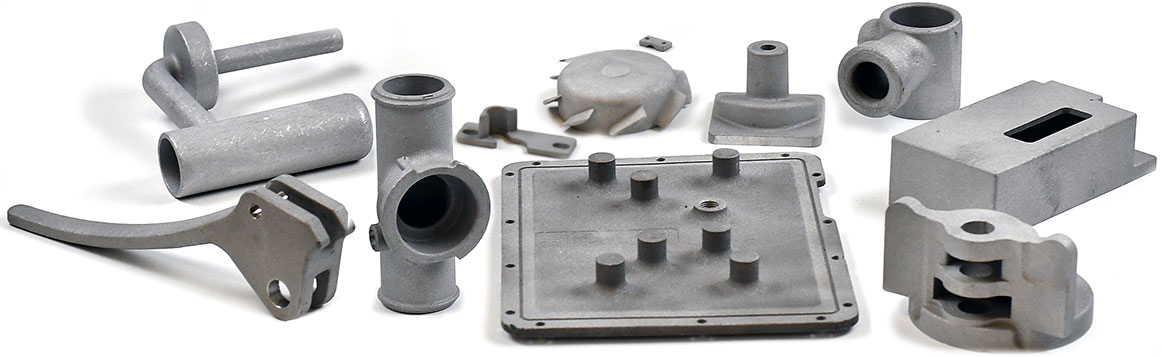

Light weight aluminum spreadings are produced with processes like sand casting, pass away spreading, and investment spreading. Molten aluminum is poured right into mold and mildews, allowed to cool down, and then got rid of, resulting in precise and sturdy why not try here elements for various applications.

What Is the Common Lifespan of Light Weight Aluminum Castings?

The common life-span of aluminum castings differs between 10 to 50 years, relying on environmental elements, use problems, and alloy composition. Proper maintenance and care can considerably prolong their resilience and efficiency in various applications.

Can Light Weight Aluminum Castings Be Reused?

Yes, aluminum castings can be recycled effectively (Aluminum Foundry). The reusing process keeps the metal's properties, making it a sustainable choice for numerous applications, consequently adding to ecological preservation and source administration within numerous markets

What Industries Are Arising for Light Weight Aluminum Spreading Applications?

Arising sectors for aluminum spreading applications consist of electrical car production, renewable resource industries, aerospace improvements, and clinical technology. These sectors leverage aluminum's lightweight, resilient properties to enhance and introduce efficiency in numerous items and systems.

While the aerospace market constantly seeks methods to boost efficiency and effectiveness, improvements in light weight aluminum castings have actually emerged as an important aspect in accomplishing these objectives. Light weight aluminum spreadings play an essential function in the construction market, offering a mix of toughness, sturdiness, and lightweight residential properties that improve architectural honesty. In consumer items making, aluminum spreadings play a crucial duty in light-weight item style, allowing for easier handling and her latest blog boosted performance. The electric and electronics sector significantly depends on aluminum spreadings for their light-weight, durable, and very conductive residential properties. Aluminum castings are produced with processes like sand spreading, pass away spreading, and investment spreading.